Elevating Lowering and Orientation gripper conveyor system/customized bottle inclined conveyor system flexible side gripper conveyor

Product Description

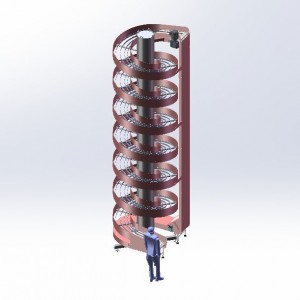

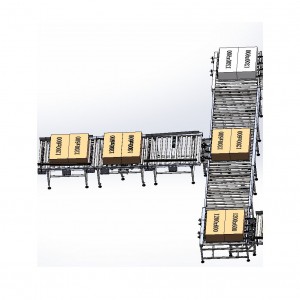

A Gripper Conveyor has many uses: it can be used to elevate products, lower products, or buffer products. It consists of 2 parallel sets of conveyor sections that are joined together on an adjustable mechanism which allows the unit to accommodate different size products. The Gripper unit can be configured to allow the product to be transferred at the same or different input/output transfer heights, The unit gentle grips the product to be transferred and guides it to the next process.

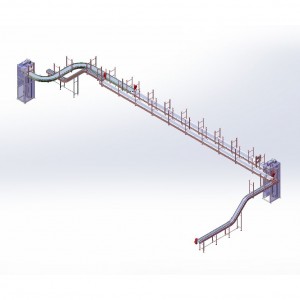

The gripper conveyor system uses two conveyor tracks facing each other to provide fast and gentle transport, horizontally and vertically. Wedge conveyors can be connected in series, if proper timing of the product flow is taken into account.

Wedge conveyors are suitable for high production rates and can be designed to save floor space. Owing to their principle of operation, the wedge conveyors are not very suitable for transport of very heavy or irregularly shaped objects.

Application: It will take a product or package smoothly from one level to another at speeds of up to 30 m/minute. Suitable applications include transport of soda cans, glass and plastic bottles, cardboard boxes, tissue paper, etc.

Advantages

-- Used to lift or lower the product directly between floors;

-- Saves floor space and conveyor length Maximize space utilization by creating buffering at ceiling levels;

-- Simple structure, reliable operation and easy maintenance;

-- Conveying goods should not be too large and too heavy;

-- To adopt manual adjustable width device, suitable for a variety of

product like bottles, cans, plastic boxes, cartons, cases;

-- Widely used in the manufacturing of beverages, foods, plastics, electronic components, printing paper, automotive parts and other industries.

-- Easy integrates with other application such as blowers, fillers, and packaging lines

-- Flexible and lightweight - easy to install and accommodate site layouts.

-- High capacity vertical transport