YA-VA Conveyor System Components Made-in-China

Essential Details

|

Applicable Industries |

Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Printing Shops, Food & Beverage Shops |

|

Showroom Location |

United States, Germany, Viet Nam, Brazil, Indonesia, India, Mexico, Russia, Thailand, South Korea |

|

Condition |

New |

|

Material |

Plastic |

|

Material Feature |

Heat Resistant |

|

Structure |

Belt conveyor |

|

Place of Origin |

Shanghai, China, Shanghai, China |

|

Brand Name |

YA-VA |

|

Voltage |

220V/318V/415V |

|

Power |

0.5-2.2KW |

|

Dimension(L*W*H) |

customized |

|

Warranty |

1 Year |

|

Width or Diameter |

300mm |

|

Machinery Test Report |

Provided |

|

Video outgoing-inspection |

Provided |

|

Marketing Type |

Ordinary Product |

|

Warranty of core components |

1 Year |

|

Core Components |

Motor, Other, Bearing, Pump, Gearbox, Engine, PLC |

|

Weight (KG) |

0.1 kg |

|

Frame Material |

SUS304/Carbon Steel |

|

Installation |

Under Technical Guidance |

|

After-sales Service |

Engineers Service Machinery Overseas |

|

Model Number |

UC/FU/FLU |

|

Brand Name |

YA-VA |

|

Application |

Machinery |

|

Certification |

ISO9001:2008; SGS |

Product Description

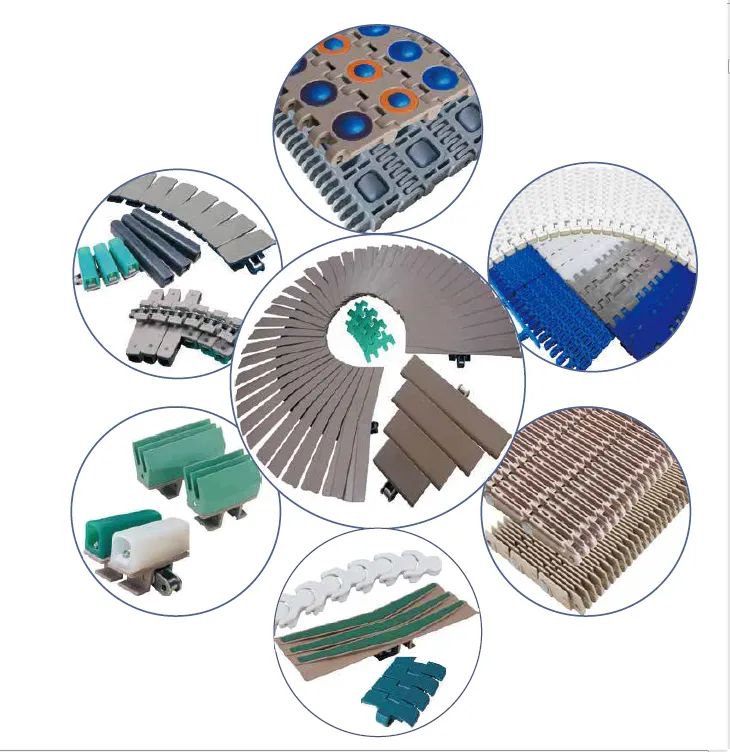

Conveyor Components: Modular belt and Chain accessories, side guide rails, guie brackets and clamps, plasstic hinge, leveling feet, cross joint clamps, wear strip, conveyor roller, side roller guide, bearings and so on.

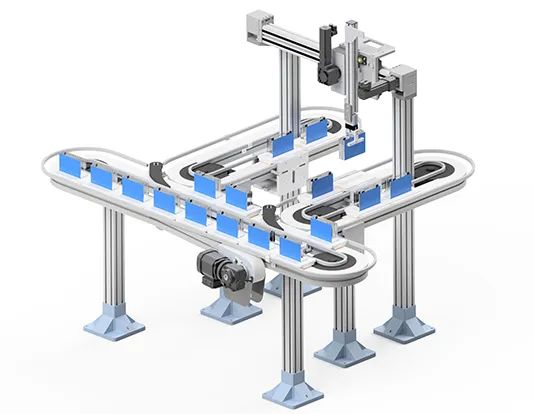

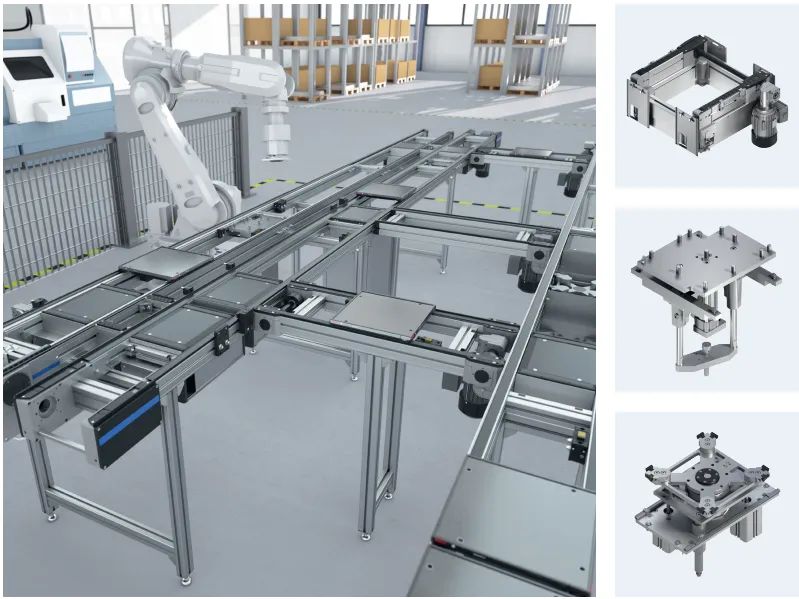

Conveyor Components: Aluminum Chain Conveyor System Parts ( support beam, drive end units, beam bracket, conveyor beam, vertical bend, wheel bend, horizontal plain bend, idler end units, aluminum feet and so on)

BELTS & CHAINS: Made for all kind of products

YA-VA offers a wide range of conveyor chains. Our belts and chains are suitable to transport products and goods of any industry and customizable to widely varying requirements.

The belts and chains consist of plastic hinged links connected by plastic rods. They are woven together by links in a wide dimension range. The assembled chain or belt forms a wide, flat, and tight conveyor surface. Various standard widths and surfaces for different applications are available.

Our product offer ranges from plastic chains, magnetic chains, steel top chains, advanced safety chains, flocked chains, cleated chains, friction top chains, roller chains, modular belts, and more. Feel free to contact us for a consultation to find a suitable chain or belt for your production needs.

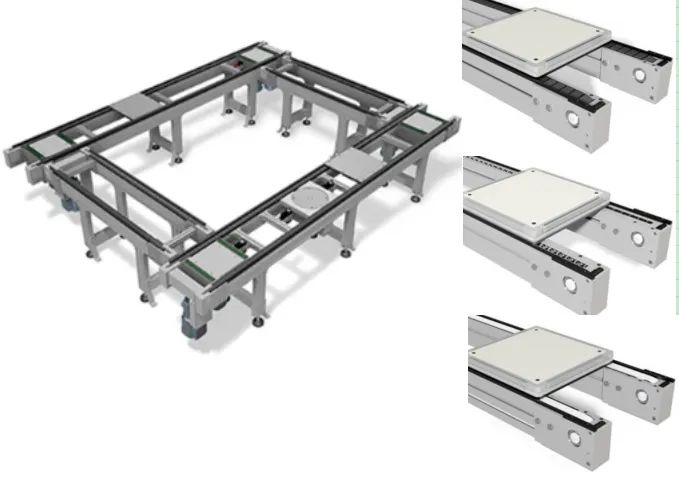

Conveyor Components: Pallets Conveyor System Parts ( tooth belt, hig-strength transmission flat belt, roller chain, dual drive unit, idler unit, wear strip, agnle bracket, support beams, support leg, adjustable feet and so on.)

Spiral Flex Conveyor

Spiral conveyors increase available production floor space

Tranport products vertically with the perfect balance of height and footprint.

Spiral conveyors lift your line to a new level.

Elevating product handling

The purpose of the spiral elevator conveyor is to transport products vertically, bridging a difference of height. The spiral conveyor can lift the line to create space on the production floor or function as a buffer zone. The spiral-shaped conveyor is the key to its uniquely compact construction that saves valuable floor space.

Our spiral elevating solutions work perfectly in filling and packing lines. Possible applications of spiral elevators range from handling individual parcels or totes to items such as shrink-wrapped bottle packs or cartons.

Customer advantages

Compact footprint

Modular & standardized

Gentle product handling

Low noise level

Different infeed and outfeed configurations

Elevation up to 10 meters

Different chain types and options

Maximum height on a compact footprint

A spiral elevator is a perfect balance of height and footprint, combined with a wide and flexible speed range.

Our spiral-shaped conveyors ensure a continuous product flow while the elevation is as simple and reliable as a normal straight conveyor.

Easy installation and trouble-free operation

The YA-VA spiral elevator is a fully functioning module that is easy to engineer according to your needs. It features a high friction plastic top chain with integrated bearings on a steel chain base, that runs against an inner guide rail. This solution ensures smooth running, low noise and long service life. Transfers to and from connecting conveyors are made easy with horizontal in- and outlet sections. Our spiral conveyors are the perfect solution for lifting or lowering of:

Packed or non-packed products

Product carriers such as pucks or cartons

Small boxes, parcels and crates

Compact Spiral elevator - ups and downs by purpose

Our minimum footprint elevating solution, the Compact Spiral elevator, increases your access to the production floor and available space. With only 750 mm in diameter, the unique Compact Spiral elevator conveyor offers a 40% smaller footprint than the most common solutions on the market. It allows manufacturers to significantly increase available production floor space by elevating and lowering products up to 10000 mm over the floor.

The Compact Spiral elevator from YA-VA is made to fit your existing production line. The integration of two compact spiral conveyors provides space for your forklifts. Our standardized and modular spiral conveyor is ready for operation within a few hours. It also ensures smooth running, low noise, and long service life.

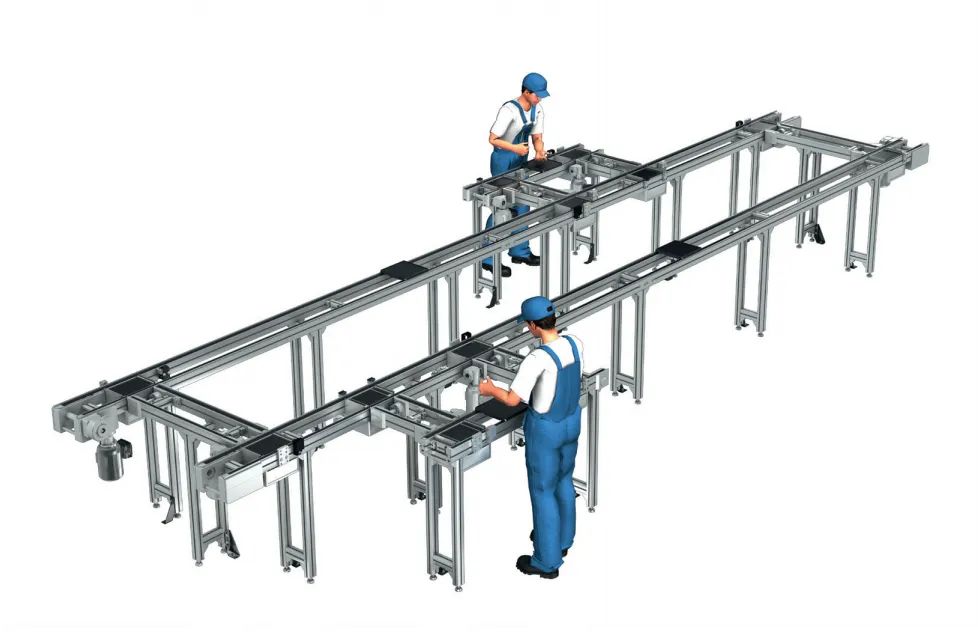

Pallet Conveyors

Pallet conveyors to track and carry product carriers

Pallet conveyors handle individual products on product carriers such as pallets. Each pallet can be adapted to varying environments, from medical device assembly to engine component production. With a pallet system, you can achieve a controlled flow of individual products throughout the complete manufacturing process. Unique identified pallets allows for creating specific routing paths (or recipes), depending on the product.

Based on the standard chain conveyor components, single-track pallet systems are a cost-efficient solution to handle smaller and lightweight products. For products with a considerable size or weight, a twin-track pallet system is the right choice.

Both pallet conveyor solutions use configurable standard modules that make it easy and fast to create advanced but straightforward layouts, allowing routing, balancing, buffering and positioning of pallets. RFID identification in the pallets enables one-piece track-and-trace and helps to achieve logistic control for the production line.

1. It is a diverse modular system that meets the requirements of a wide range of different products.

2. Diverse, sturdy, adaptable;

2-1) three types of conveyor media (polyamide belts, toothed belts and accumulation roller chains) which can be combined together to meet the needs of the assembly process

2-2)Workpiece pallets dimensions (from 160 x 160 mm up to 640 x 640 mm) specifically designed for the product sizes

2-3)A high maximum load of up to 220 kg per workpiece pallet

3. Apart from the different types of conveyor media, we also provides an abundance of specific components for curves, transverse conveyors, positioning units and drive units. The time and effort spent on planning and designing can be reduced to a minimum using predefined macro modules.

4.Applied to many industry, such as new-energy industry, Automobile, battery industry and so on

Packaging & Shipping

For components, inside is carton boxes and outside is pallet or ply-wood case.

For conveyor machine, packed with plywood boxes according to products sizes.

Shipmethod: based on customer's request.

FAQ

Q1. Are you trading company or manufacturer?

A: We're manufacturer and have our own factory and experienced technicans.

Q2. What is your terms of payment?

A: Conveyor components: 100% in advance.

Conveyor system: T/T 50% as deposit, and 50% before delivery.

Will send photos of conveyor and packing list before you pay the balance.

Q3. What is your terms of delivery and delivery time?

A: EXW, FOB, CFR, CIF, DDU, etc.

Conveyor components: 7-12 days after received the PO and payment.

Conveyor machine: 40-50 days after received the PO and down payment and confirmed drawing.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5. What is your sample policy?

A: We can supply some certain small sample if ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and sincerely do business, no matter where they come from.